Next-generation SmartScope M130 introduces dramatic improvements in image accuracy, optics and productivity for manufacturers of large and heavy mechanical components

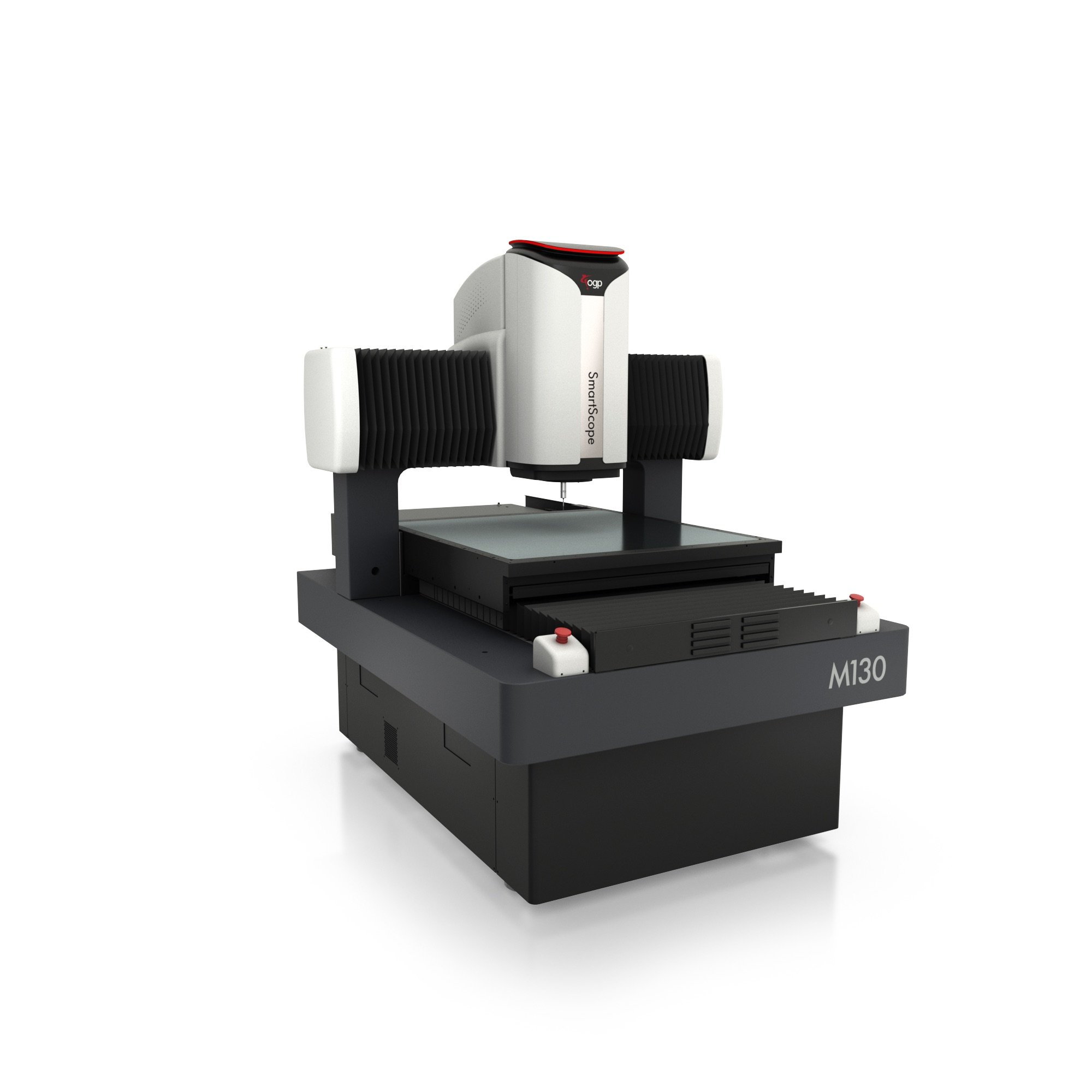

Optical Gaging Products (OGP®), a leading global manufacturer of precision optical and multisensor metrology systems for industrial quality control, is proud to announce the latest addition to the evolution of the SmartScope® family of 3D multisensor metrology systems: the SmartScope M130.

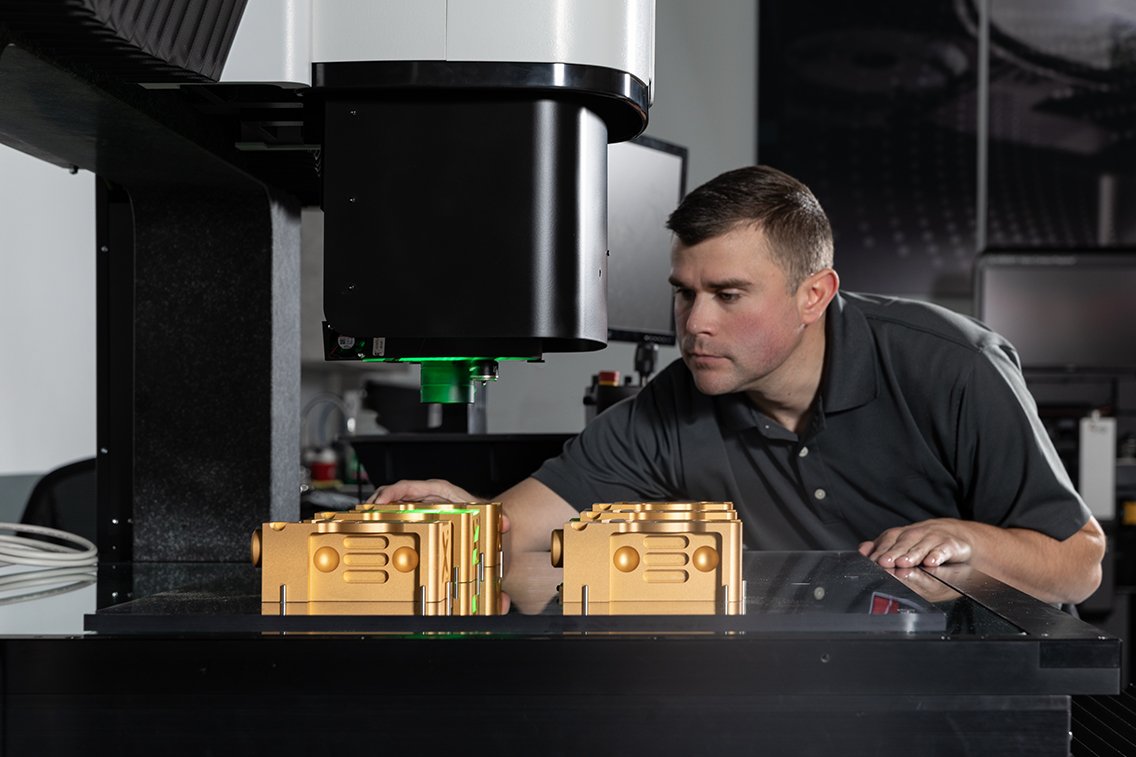

For manufacturers of large and heavy mechanical components, the next-generation SmartScope M130 system delivers dramatic improvements in image accuracy, optics and productivity, thanks to a new, large-format 3D multisensor video measurement platform.

Tim Fantauzzo, vice president and director of sales for North America at OGP, commented, “The SmartScope M-Series family has been rapidly adopted by manufacturers seeking unmatched confidence in repeatability and reliability. Larger components can obviously contain many more detailed features. The M130 optical system is truly telecentric without distortion, so manufacturers making large, heavy components can achieve more accurate measurements, especially at low magnification levels, evaluating many more component features in the field of view.”

At the heart of the SmartScope M130 is the patented* IntelliCentric-M optical system, featuring fixed optics paired with a 20-megapixel camera featuring proprietary VIRTUAL ZOOM™ technology. Built from the ground up at OGP's headquarters in Rochester, New York, the streamlined IntelliCentric-M optics employ a suite of unique technologies that allow for instantaneous magnification changes throughout the entire zoom range, similar to a traditional mechanical zoom system, resulting in reduced run time and maintenance downtime.

The SmartScope M130 measurement system is the ideal choice for manufacturers producing large parts and requiring advanced productivity solutions. The IntelliCentric-M optical system, combined with advanced sensors, illumination and accessories, achieves class-leading optical measurement speeds.

With a large standard XYZ-axis travel of 790 x 815 x 200 mm, an optional 300 or 400 mm Z-axis, and a payload capacity of 75 kg (165 lb), the SmartScope M130 brings the benefits of the next generation M-Series systems to manufacturers producing large parts. An innovative new base design results in a lower measuring table height, allowing users to easily load and unload heavy parts or large fixtures.

President Steve Flynn said, "Since 1992, OGP SmartScope systems have helped thousands of manufacturers worldwide gain confidence in their quality control. With the SmartScope M130, we've integrated the latest advances in optics and software into a larger format, creating the next generation of cutting-edge metrology solutions for manufacturers of large and heavy parts.

The M-Series family of systems takes full advantage of the advanced edge detection algorithms, parallel processing, and routine optimization found in ZONE3 metrology software to ensure maximum productivity and increased accuracy for manufacturers in any industry. We're thrilled that our customers producing large parts have been able to appreciate these benefits already present in their compact M-Series measurement systems, as well as new OGP machine users, who will discover how the new SmartScope M130 model will significantly improve their inspection and quality control operations."

Industriale.it certification

Industriale.it certification